Eagle Ford Shale Operator Boosts Efficiency by 30% with Corva

Maximize Capital & Operational Efficiency

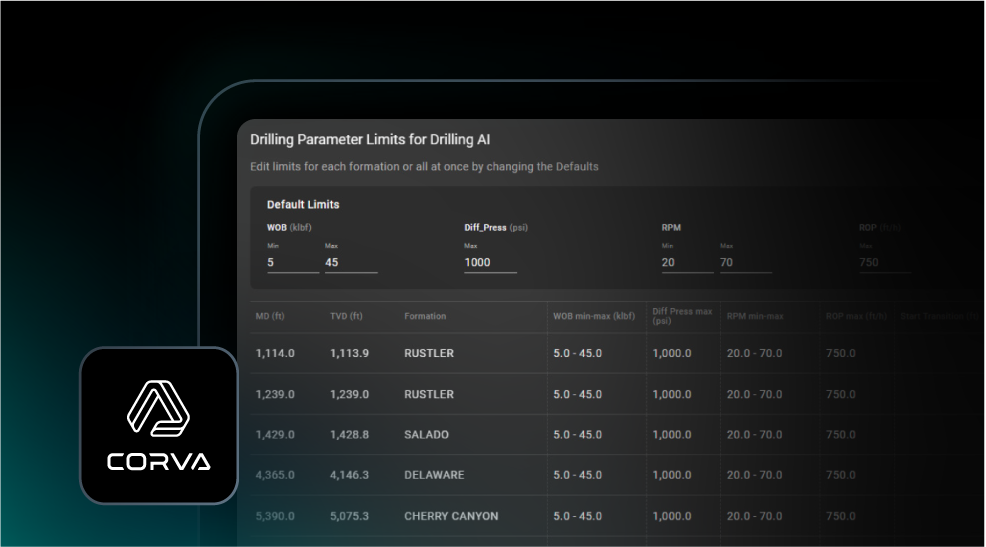

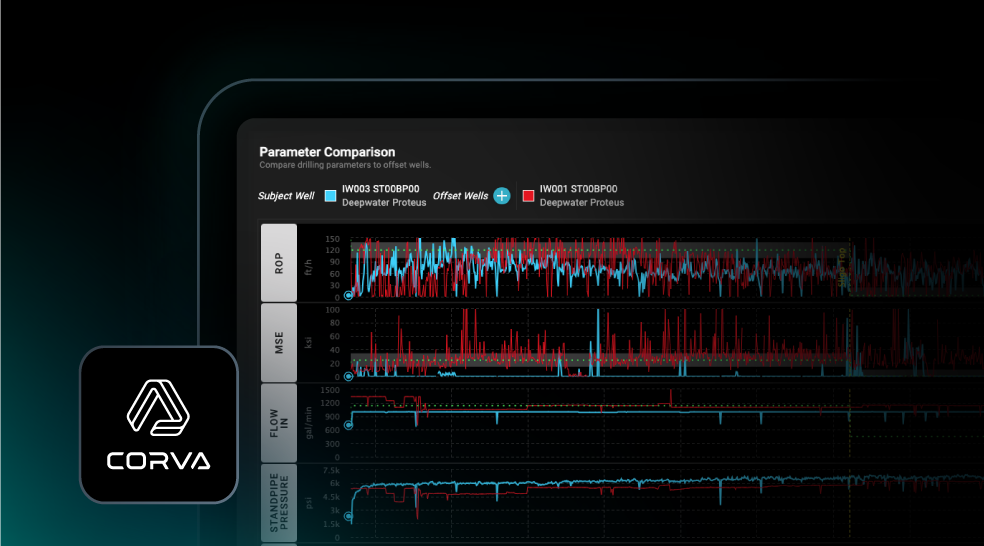

An Eagle Ford Shale operator aimed to enhance drilling performance on a new six-well pad, focusing on significantly boosting operational efficiency, reducing costs, and streamlining the drilling process to achieve substantial financial savings. To meet these goals, the operator implemented Predictive Drilling technology across the vertical, intermediate, and lateral sections of the wells, which led to improved drilling performance and considerable cost savings.

Key Results & Value Delivered

The use of Predictive Drilling resulted in notable reductions in drilling time, outperforming the fastest offset well by 0.5 days. Significant improvements were made on the last lateral, which was drilled 1.5 days faster than the offset wells. By utilizing this advanced technology, the operator saved $315,000 per pad, realized a 30% improvement in capital efficiency, and achieved a 91% utilization rate of predictive drilling. This marked a significant advancement in their drilling efficiency and overall cost-effectiveness.